A06B-0215-B000 is a servo motor under Fanuc brand, the following is its detailed introduction:

Basic Information

Brand: Fanuc is a world-renowned manufacturer specializing in the production of industrial automation equipment and robots, and is known in the industry for its high-quality, high-precision and high-reliability products.

Model: A06B-0215-B000.

Voltage: Typically 149V or 176V.

Power mode: AC.

Power: 1000W.

Features:

High-precision positioning: The use of advanced encoder technology can achieve accurate position control, which can meet the high requirements of machine tools and other equipment for machining accuracy and ensure the stability of product quality.

High response speed: The rotor inertia of the motor is small, the acceleration and deceleration time is short, and it can quickly respond to the instructions of the control system, realize fast start and stop and frequent forward and reverse rotation, and improve production efficiency.

High reliability: Fanuc's products strictly follow high standards in the design and manufacturing process, have good anti-interference ability and stability, and can operate stably for a long time in harsh industrial environments, reduce equipment failure rate and reduce maintenance costs.

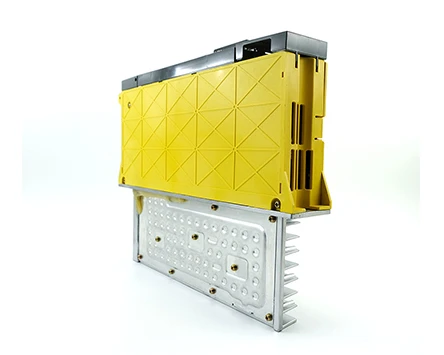

Compact structure: compact design, small size, light weight, easy to install and integrate into various mechanical equipment, save space, improve the overall compactness and aesthetics of the equipment.

Good compatibility: It can be seamlessly connected and matched with other CNC systems, drives and other equipment of Fanuc to form a complete automatic control system, and can also be compatible with some related equipment of other brands, which is convenient for users to upgrade and transform the system.

Fields of application

Machine tool field: widely used in all kinds of CNC machine tools, such as machining centers, lathes, milling machines, grinding machines, etc., to provide power for the feed axis and spindle of machine tools, to achieve accurate cutting, drilling, milling and other processing operations, to ensure machining accuracy and surface quality.

Industrial automation production line: In the industrial automation production line such as automobile manufacturing, electronic equipment manufacturing, and machining, it is used to drive the joints of robots, the transmission devices of conveyor lines, and material handling equipment to realize automated production processes and improve production efficiency and product consistency.

Other fields: It can also be applied to printing and packaging machinery, textile machinery, medical equipment, semiconductor manufacturing equipment and other industries, providing precise motion control for these equipment to meet the special needs of different industries.

_20250528152633.webp)

_20250528152634.webp)

_20250528152635.webp)

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский العربية

العربية Türkçe

Türkçe Jawa

Jawa